Asymtek To Feature Calibrated Process Jet Dispensing Of Catalyst Ink On Fuel Cell Membranes At FC2008 Japan, Booth #1-002

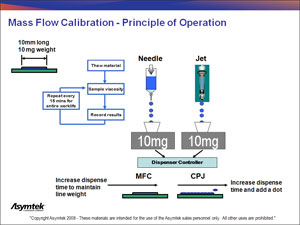

Carlsbad, CA - Asymtek, a Nordson company and leader in dispensing and jetting technologies, will feature Mass Flow Calibration (MFC)  jet dispensing of catalyst ink on fuel cell membranes at the 4th International Hydrogen and Fuel Cell Expo, FC2008, in Booth #1-002. The expo is held February 27-29, 2008 at Tokyo Big Sight in Tokyo, Japan.

jet dispensing of catalyst ink on fuel cell membranes at the 4th International Hydrogen and Fuel Cell Expo, FC2008, in Booth #1-002. The expo is held February 27-29, 2008 at Tokyo Big Sight in Tokyo, Japan.

Asymtek's coating and dispensing technologies apply catalyst inks onto membranes in electrode assemblies (MEA) of proton exchange /direct methanol fuel cells. One of the difficulties in coating a membrane is to control the metal loading. This control is easily done with Asymtek's integrated balance scale. The amount of ink is software controlled by entering the weight needed for the MEA into Asymtek's Fluidmove for Windows XP software. Asymtek will present several types of dispensing and coating technologies for increased flexibility: discrete dot dispensing, large area coating, and pulse spray coating. Any of these coating technologies will automatically calibrate themselves.

Discrete dot dispensing uses the DispenseJet DJ-9000 valve to create specific patterns with high edge definition and exact placement of these expensive inks. The DispenseJet DJ- 2200 non-contact jet coats in tight spaces and can dispense lines just 3mm wide (0.125 in.). The pulse spray coats both large and small areas. Asymtek offers the combination of these technologies to give the customer a highly flexible, high throughput coating system.

SOURCE: Asymtek